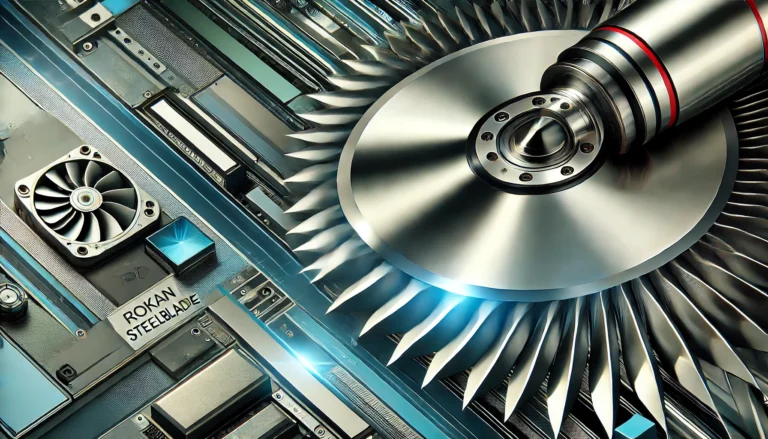

The Rokan Steelblade is transforming the cutting tool industry with its advanced design, materials, and exceptional performance. This state-of-the-art blade is quickly gaining recognition across multiple sectors for its precision, durability, and versatility. Whether you’re working in manufacturing, construction, or aerospace, the Rokan Steelblade offers a level of reliability and efficiency that traditional tools simply can’t match. In this article, we’ll dive into the key features, benefits, and applications of the Rokan Steelblade, as well as its maintenance and environmental impact.

The Cutting Edge: What Makes the Rokan Steelblade Stand Out?

The Rokan Steelblade is not just any cutting tool. What sets it apart from traditional tools is its precision engineering and the use of high-performance materials. The blade is crafted from a specialized blend of high-carbon steel and alloys, which enhances its strength and edge retention. This results in a cutting tool that stays sharper longer, providing consistent results across a variety of applications. The superior material composition ensures that the Rokan Steelblade is more resilient to wear and tear compared to conventional cutting tools.

Exceptional Durability: How the Rokan Steelblade Stays Sharp for Longer

One of the most compelling reasons professionals in various industries are turning to the Rokan Steelblade is its exceptional durability. Thanks to the high-carbon stainless steel and advanced alloys used in its construction, the blade is able to maintain its sharpness for extended periods of time. This is crucial in industries where precision and cutting efficiency are vital. The Rokan Steelblade reduces the need for frequent sharpening, saving time and money in the long run. Whether you’re cutting through metal, plastic, or composite materials, the blade’s longevity ensures fewer interruptions and greater productivity.

Rokan Steelblade’s Ergonomic Design: Enhancing Safety and Comfort

Another standout feature of the Rokan Steelblade is its ergonomic design. Unlike many traditional cutting tools that can be uncomfortable or even hazardous to use over extended periods, the Rokan Steelblade has been designed with the user in mind. The tool’s handle is integrated to offer optimal grip and control, reducing the risk of hand fatigue and accidents. This ergonomic consideration makes it an ideal choice for professionals working in demanding environments like construction sites or manufacturing floors, where safety is a top priority.

Versatility in Application: Where Can You Use the Rokan Steelblade?

The Rokan Steelblade is incredibly versatile and can be used in a variety of industries. Below are some of the sectors where it is making a significant impact:

Manufacturing Industry

In manufacturing, precision is everything. The Rokan Steelblade is ideal for cutting, trimming, and shaping metals, plastics, and composites. Its sharpness and durability allow manufacturers to work with greater efficiency, reduce waste, and maintain high-quality standards. Whether it’s for intricate cutting or heavy-duty tasks, the Rokan Steelblade delivers consistent results.

Construction Industry

The construction industry also benefits greatly from the Rokan Steelblade. Contractors and tradespeople often need to cut through a variety of materials such as wood, drywall, and plastic. With the Rokan Steelblade, they get a tool that can handle multiple materials without losing its sharpness, allowing them to complete tasks faster and more accurately.

Aerospace Applications

In the aerospace industry, where the tolerance for error is minimal, the Rokan Steelblade plays a crucial role in shaping and cutting materials for aircraft and spacecraft components. Its precise cutting ability and durability ensure that aerospace parts are made to the highest standards, making the Rokan Steelblade a trusted tool in this highly regulated industry.

Maintenance of the Rokan Steelblade: Keep It in Top Shape

To ensure that your Rokan Steelblade continues to perform at its best, regular maintenance is key. Fortunately, caring for this tool is straightforward:

Proper Handling and Storage

To prevent damage, always handle the Rokan Steelblade carefully. Dropping or mishandling it could cause irreparable damage to the blade. Additionally, store the blade in a dry, safe location to prevent rust and corrosion. Proper storage extends the tool’s lifespan and ensures that it remains in peak condition.

Cleaning and Sharpening

Cleaning your Rokan Steelblade after each use is essential. A dry cloth can be used to wipe off dirt and debris. For deeper cleaning, mild detergent and warm water can help. After cleaning, dry the blade thoroughly to avoid moisture buildup, which could lead to rust.

Over time, the blade may require sharpening. While it can maintain its edge for longer than most cutting tools, occasional sharpening with a professional service or sharpening stone will keep it performing at its best.

The Environmental Impact: How the Rokan Steelblade Contributes to Sustainability

Sustainability is a growing concern in the manufacturing industry, and the Rokan Steelblade is designed with environmental impact in mind. Unlike disposable tools that require frequent replacements, the durability of the Rokan Steelblade reduces waste significantly. The blade’s long lifespan means that fewer tools need to be manufactured, used, and discarded, leading to a lower environmental footprint. Additionally, the manufacturing process of the Rokan Steelblade is eco-friendly, with a focus on reducing waste and conserving natural resources.

Cost Efficiency: The Value Proposition of the Rokan Steelblade

While the initial cost of the Rokan Steelblade might be higher than traditional cutting tools, the long-term savings it offers make it a cost-effective investment. Thanks to its durability and extended sharpness, businesses can expect reduced maintenance and replacement costs. The Rokan Steelblade also boosts productivity by minimizing downtime for tool maintenance or replacement, offering a high return on investment over time.

Frequently Asked Questions (FAQs)

1. What makes the Rokan Steelblade different from traditional cutting tools?

The Rokan Steelblade stands out due to its high-carbon steel composition and precision manufacturing. This allows the blade to maintain its sharpness for longer periods, providing exceptional durability and cutting efficiency compared to traditional tools.

2. Can the Rokan Steelblade be used for cutting metal?

Yes, the Rokan Steelblade is highly effective for cutting a variety of materials, including metal, plastics, composites, and wood, making it a versatile tool in many industries.

3. How do I maintain my Rokan Steelblade?

To keep your Rokan Steelblade in optimal condition, make sure to clean it after each use, store it properly, and sharpen it when necessary. Regular maintenance will ensure its longevity and high performance.

4. What industries benefit from using the Rokan Steelblade?

The Rokan Steelblade is widely used in industries such as manufacturing, construction, and aerospace, where precision and durability are essential for cutting various materials.

5. Is the Rokan Steelblade environmentally friendly?

Yes, the Rokan Steelblade is designed with sustainability in mind. Its long lifespan reduces the need for frequent replacements, and its eco-friendly manufacturing process helps reduce waste and resource consumption.