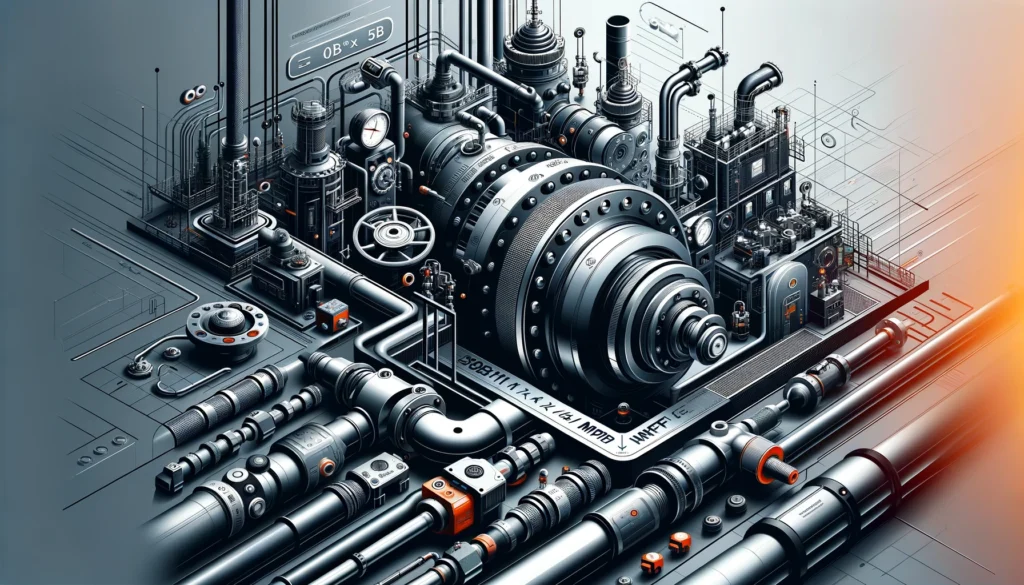

In the realm of industrial components, the 50B11H x 3/4 MPB stands out as a robust and reliable mechanical connector used extensively across various high-demand environments. This article delves into the specifications, applications, and maintenance practices of this crucial fitting, providing essential insights for professionals in the engineering, manufacturing, and maintenance sectors.

Overview of 50B11H x 3/4 MPB

The 50B11H x 3/4 MPB is a type of mechanical fitting known for its durability and versatility. Made from high-strength materials such as brass and stainless steel, it is designed to withstand harsh operational conditions including high pressures and temperatures. Its corrosion resistance ensures long-term reliability, making it a staple in industries such as HVAC, automotive, and industrial manufacturing.

Key Features and Benefits

Durability and Material Composition

Constructed from materials known for their strength and resistance to environmental challenges, the 50B11H x 3/4 MPB offers exceptional durability. The choice of brass and stainless steel not only enhances its longevity but also provides significant resistance against corrosion, which is crucial for applications involving exposure to moisture or chemicals.

Versatility Across Industries

One of the most significant advantages of the 50B11H x 3/4 MPB is its versatility. This fitting finds its use in diverse settings, from plumbing systems to complex automotive networks, where secure and reliable connections are paramount. Its ability to adapt to different industrial needs while maintaining high performance makes it invaluable to technicians and engineers.

Installation and Maintenance

Installation Guidelines

Installing the 50B11H x 3/4 MPB is straightforward, provided that the correct procedures are followed. Essential steps include preparing the installation area, applying appropriate thread sealants, and conducting thorough checks for leaks post-installation. These practices ensure that the fitting is installed correctly and performs optimally in its designated role.

Maintenance Best Practices

To maximize the lifespan and efficiency of the 50B11H x 3/4 MPB, regular maintenance is crucial. Routine inspections should be carried out to identify and address potential issues such as wear and tear or corrosion. Proper tightening and the use of correct tools can prevent common problems like leaks and thread damage, which are vital for maintaining system integrity.

Practical Applications

Industrial Significance

In industrial environments, the 50B11H x 3/4 MPB is essential for managing fluid dynamics and ensuring the reliability of mechanical systems. Its ability to handle varying pressures and temperatures makes it suitable for high-stakes applications, including hydraulic systems and critical manufacturing processes.

Automotive and HVAC Use

In the automotive industry, this fitting is crucial for assembling secure, leak-proof connections in engines and fuel systems. Similarly, in HVAC systems, the 50B11H x 3/4 MPB ensures that air and fluid flow are managed efficiently, which is vital for system stability and energy efficiency.

Strategic Value and Economic Impact

Cost-Effectiveness and Return on Investment

The economic implications of incorporating the 50B11H x 3/4 MPB into various systems cannot be overstated. Its cost-effectiveness is derived from the long-term savings it offers businesses by minimizing the need for frequent replacements and repairs. The initial investment in these high-quality fittings results in lower operational costs, thanks to reduced downtime and maintenance expenses. This makes the 50B11H x 3/4 MPB a wise choice for budget-conscious projects seeking durable solutions.

Enhanced System Efficiency and Performance

The 50B11H x 3/4 MPB not only provides a reliable mechanical solution but also enhances the overall efficiency of the systems it integrates with. By ensuring a secure and tight connection, it minimizes potential leaks and energy losses, which is crucial in systems like HVAC and hydraulic machinery where efficiency translates into energy savings and operational effectiveness.

Risk Management and Safety Features

Safety Enhancements

The robust construction of the 50B11H x 3/4 MPB contributes significantly to the safety aspects of industrial and automotive systems. Its ability to withstand high pressures and temperatures reduces the risk of catastrophic failures, which is particularly important in industries where safety is paramount. By using fittings that exceed standard requirements, businesses can ensure a safer working environment and compliance with regulatory standards.

Reliability in Extreme Conditions

The choice of materials and design specifications allows the 50B11H x 3/4 MPB to operate reliably in extreme environmental conditions. Whether it’s exposed to corrosive substances or extreme temperatures, this fitting remains functional, maintaining its integrity and performance. This reliability is crucial for industries such as oil and gas exploration, aerospace, and other applications demanding uncompromised performance in challenging conditions.

Innovation and Future Outlook

Technological Advancements

As industries continue to evolve, the demand for more advanced and reliable components like the 50B11H x 3/4 MPB increases. Innovations in material science and manufacturing processes are likely to enhance the capabilities of these fittings further, making them even more integral to future industrial applications.

Sustainability and Environmental Considerations

With a growing emphasis on sustainability, the environmental impact of manufacturing and using industrial components is under scrutiny. The 50B11H x 3/4 MPB, made from materials that are both durable and recyclable, aligns with the push towards more sustainable manufacturing practices. Future developments may focus on reducing the ecological footprint of these components while maintaining or enhancing their performance and reliability.

Conclusion

The 50B11H x 3/4 MPB is more than just a component; it is a fundamental element that enhances the reliability and efficiency of various mechanical systems. Its robust design, combined with ease of installation and maintenance, makes it a preferred choice for professionals looking to optimize their operations. By adhering to the guidelines and practices outlined, users can ensure they fully leverage the benefits of this versatile connector.

FAQs About the 50B11H x 3/4 MPB

- What materials are used to make the 50B11H x 3/4 MPB?

- The 50B11H x 3/4 MPB is typically made from brass and stainless steel, known for their durability and corrosion resistance.

- Where is the 50B11H x 3/4 MPB commonly used?

- It is used across various industries, including automotive, HVAC, and industrial manufacturing, for its ability to handle high pressures and temperatures.

- What are the key benefits of using the 50B11H x 3/4 MPB?

- Key benefits include high durability, versatility across different applications, and resistance to harsh environmental conditions.

- How is the 50B11H x 3/4 MPB installed?

- Installation involves preparing the area, applying thread sealant, and ensuring a tight, leak-free connection.

- What maintenance practices are recommended for the 50B11H x 3/4 MPB?

- Regular inspections, proper tightening, and prompt repairs or replacements as needed are crucial for maintaining its performance.